In a nuclear power plant all structural members that could affect nuclear safety are required to be designed to resist seismic forces. These items can range from main building structures to duct work.

Temporary Duct Analysis:

This problem was performed for a nuclear power plant. Because of maintenance work being performed on one room cooler, it was necessary to install temporary duct work from a different cooler to cool the room during the maintenance operation. The new duct had temporary supports to hold it in place. The client requested that we analyze the duct and its supports to determine if the configuration would be stable during a seismic event.

The duct and its supports were modeled in our ANSYS Finite Element Analysis (FEA) software. Based on our initial results, some minor modifications were recommended to the support system.

The final design and configuration were determined to be stable and acceptable, ensuring that all nuclear safety requirements were satisfied.

Certifying Conduit Support as Seismic II/I:

Conduit re-routing required the modification of the conduit supports. There was safety related equipment located under these non-safety related conduit. Because of this, the support system was required to be stable under seismic loading. Archon was contracted to perform this seismic analysis.

Our approach was to model the system in our Finite Element Analysis (FEA) software. We applied the normal and seismic loads and reviewed the stress and deflection output to verify the limits were not exceeded.

Based on our results we were able to provide the client with a complete design that satisfied the plant requirements.

Storage Building Foundation Modification:

The client was replacing a storage building with a new building. The building manufacturer provided a foundation design that the client determined was not cost effective. Archon was requested to review the new building loads and determine if any of the existing foundation could be used, rather than removing it and replacing it with a new foundation.

This was a challenging project because column base plates did not line up well with the existing foundation grade beams. Our solution was to model the existing foundation in our Finite Element Analysis (FEA) software, apply the building loads, then investigate the soil bearing pressures and foundation stresses.

Based on our evaluation we were able to provide the client with base plate and anchor designs that matched the new building column locations, without modifying the existing foundation. This saved the client a significant amount of cost.

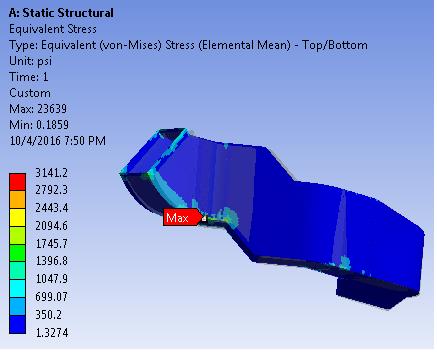

Seismic Qualification of a Chemical Addition Tank:

While performing a review our client realized that, though this chemical addition tank was classified as seismic II/I, an analysis was not on file to justify the qualification. Archon was contracted to perform the analysis.

This tank had three pipe lines that connected to it. Our approach was to perform a pipe stress analysis on the three lines, verify that they were seismically stable, and apply their reaction loads to a Finite Element Analysis (FEA) model of the tank. The tank contained fluid so our analysis also included forces generated by sloshing action within the tank.

Tank, member, weld and anchor bolt stresses were reviewed. Our analysis showed that the tank would be stable during a seismic event, which justified the client’s tank classification as seismic II/I.