During maintenance in a nuclear power plant, heavy equipment often must be rigged and transported over structures that are between the load and safety related equipment. The question is “will the structure protect the safety related equipment if the load is dropped?”.

Drop over Fuel Storage Rack:

This analysis performed a review to determine the maximum acceptable drop height of a two ton load passing over a new fuel storage rack. The load reflected a fuel assembly. The results of this analysis would determine the maximum height that the crane operator could lift the load over the area of concern.

The rack was modeled in one of our Finite Element Analysis (FEA) programs.

The load was modeled to impact the rack with a velocity based on drop height. The model included plastic material. Based on the plastic strain results and deflections it was determined that a maximum drop height of 16.5 ft would be acceptable. The basis for the conclusion was that all plastic strains were below the allowable strain limit of the material and deflections were not excessive enough to cause impact to the stored fuel assemblies.

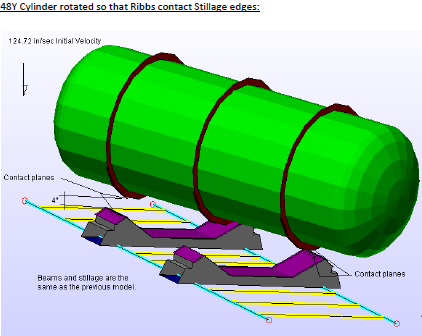

UF6 Cylinder Drop:

The client's concern in this project was that a possible hazardous release could occur in a uranium hexafluoride container if the container is dropped on a temporary storage rack.

The container and rack were modeled in our Finite Element Analysis (FEA) software. The material was modeled as plastic material because yielding was expected. The intent of the FEA analysis was to compare impact strains to failure strains in the container material. Several models were run to reflect all possible impact points.

Our conclusions showed that at the maximum possible drop height, the strains in the container would be below the limiting failure strains, therefore a hazardous release would not occur.